Bi-directional communication between the PLC and laser marking devices now possible with Lanmark Controls LEC laser marking boards.

An integral part of today’s automated factory, the PLC (programmable logic controller) continuously monitors the state of devices and machinery within the factory. The PLC communicates directly with devices, the factory network, and other PLCs on the network, and then controls its Input/Output (I/O) signals based on information it receives from these devices.

This bi-directional communication between the PLC and the connected machines or devices is critical for manufacturers running high-speed automation equipment within a “connected” factory. Until recently, however, laser marking lacked the capability to communicate with the PLC and thus wasn’t part of the connected factory.

“It’s been a real challenge for manufacturers who want to incorporate automated part marking into their processes,” says David Sweet, President of Mecco Marking and Traceability. “Custom interfacing needed to be written via a RS-232 or TCP/ IP interface to integrate laser or dot peen marking equipment. The programming time required to create this interfacing took many hours – with additional time required anytime the software or firmware was upgraded.”

With Lanmark Control’s Remote API and LEC “smart” laser marking control boards, Mecco has eliminated the hours of custom programming needed in order to have their laser marking systems communicate seamlessly with the factory PLC.

The Remote API explained

The Remote API, or Application Programming Interface, is a set of formatted messages that allow software applications to talk directly with each other. This communication can be scripted or programmed to happen behind the scenes without any intervention on the part of the user.

Common examples of APIs include any type of software-to-software integration, such as when a program on your desktop “syncs” or integrates with another program or another device – for example a CRM that works seamlessly with an email application or a smartphone app that allows you to check in for your flight or monitor flight status.

A Remote API works similarly to an API except for one difference: it allows seamless communication between software and a remote device or machine – for example, the PLC’s software and a laser marking machine that incorporates Lanmark Control’s LEC laser marking boards.

LEC-1 solves many challenges for manufacturers

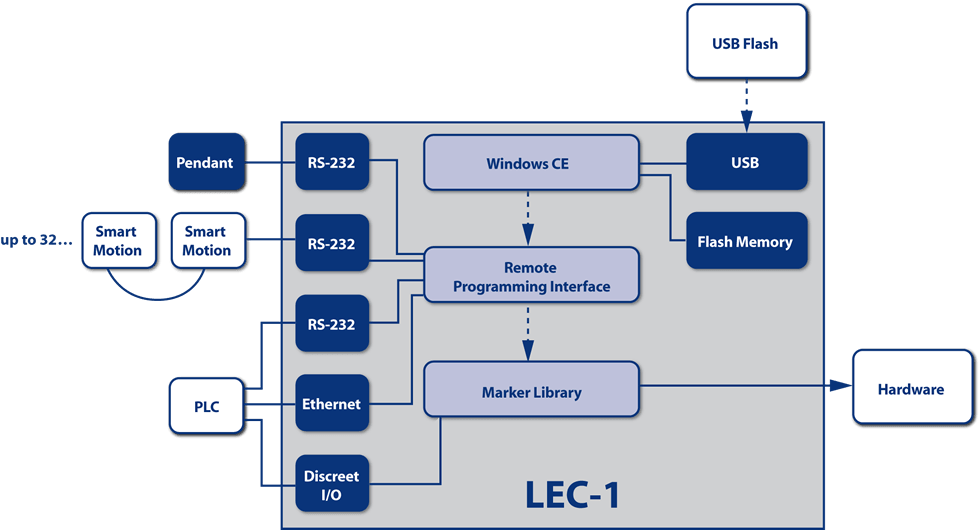

Due to its ability to communicate with a PLC, factory network, or PC via the Remote API, the LEC allows manufacturers to manage multiple jobs or automation lines simultaneously while eliminating the need for PCs on the factory floor. The laser marking machine and its integrated LEC board become part of the “connected” factory by simply plugging it into an Ethernet connection. Each LEC board then becomes a node on the network and is able to communicate with the controller through the Remote API.

Mecco streamlines PLC communication for its customers

Using Lanmark Control’s Remote API, Mecco developed EtherMark™, an EtherNet IP communication solution that effectively streamlines the communication to, and the automation of, their OEM laser marking systems that incorporate Lanmark’s LEC boards – a critical benefit for their customers who run automated factories.

With EtherMark™, a Mecco customer can immediately load the PLC Add-On Profile that includes the most used laser marking command sets, such as loading files, sending dynamic information or applying XY mark positions. Instead of spending hours coding the communication pathway, Mecco customers are up and running in 8 minutes – a significant time and cost savings.

“Due to Lanmark’s Remote API and the LEC’s ability for bi-directional communication with the PLC, we can now do what couldn’t do before: seamlessly connect our clients’ PLCs with their laser marking devices,” says Sweet.

About the LEC-1

- Designed for high-speed manufacturing environments that require dynamic laser marking capabilities, the LEC-1 is the only product of its type to deliver true stand-alone capabilities.

- A “smart” control board, the LEC-1 enables execution of jobs remotely over the network (streaming mode) or direct execution via communication with the board in stand-alone mode.

- As a powerful standalone controller, the LEC-1 is ready to accept your commands. The Remote API command set provides extended functionality to load jobs, run jobs, interact with objects, change administration settings, and many other functions.

To learn more, contact us.